ASME – Elliptical Tank Heads

Customized size

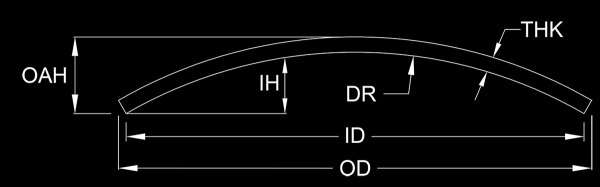

Dished Only Tank Heads

Dished Only

Realiable quanlity

Affordable price

Dished Only Hot Pressed Code Dished Ends: Precision, Strength, and Reliability

Material | Carbon Steel;Stainless Steel; Aluminum; Exotic Alloys; Special Steel... |

Main Products | Torispherical; 2:1Semi Ellipsoidal; Hemispherical; Flat Bottom; Floating Heads; Tank Heads; Dish Heads; Dished Ends; Pipe Caps.... |

Surface Treatment | 1. Intermediate & Final stage Heat Treatments; |

Technology | 1.Cold & Hot forming ; |

Test | 1. Liquid Penetrant Examination; |

Dished-only ends, also known as dish-only heads or dished-only tank heads, are essential components across various industries. These uniquely crafted elements provide structural integrity and secure containment in pressure vessels, truck tanks, silos, and more. At Haipei Industry, we manufacture high-quality dished-only ends, ensuring compliance with industry standards while meeting our clients' specific needs.

Dished-only ends undergo a meticulous production process to ensure durability and precision. The manufacturing involves either hot pressing for standard sizes or progressive cold pressing for non-standard dimensions. The key steps include:

Material Selection: Choosing the appropriate material based on the application, including carbon steel, stainless steel, and specialty alloys.

Cutting and Sizing: Metal discs are cut from large sheets according to the required specifications.

Pressing and Shaping: The discs are pressed into a concave shape, forming the signature curvature of dished-only ends.

Quality Assurance: Rigorous testing ensures every piece meets industry standards and project requirements.

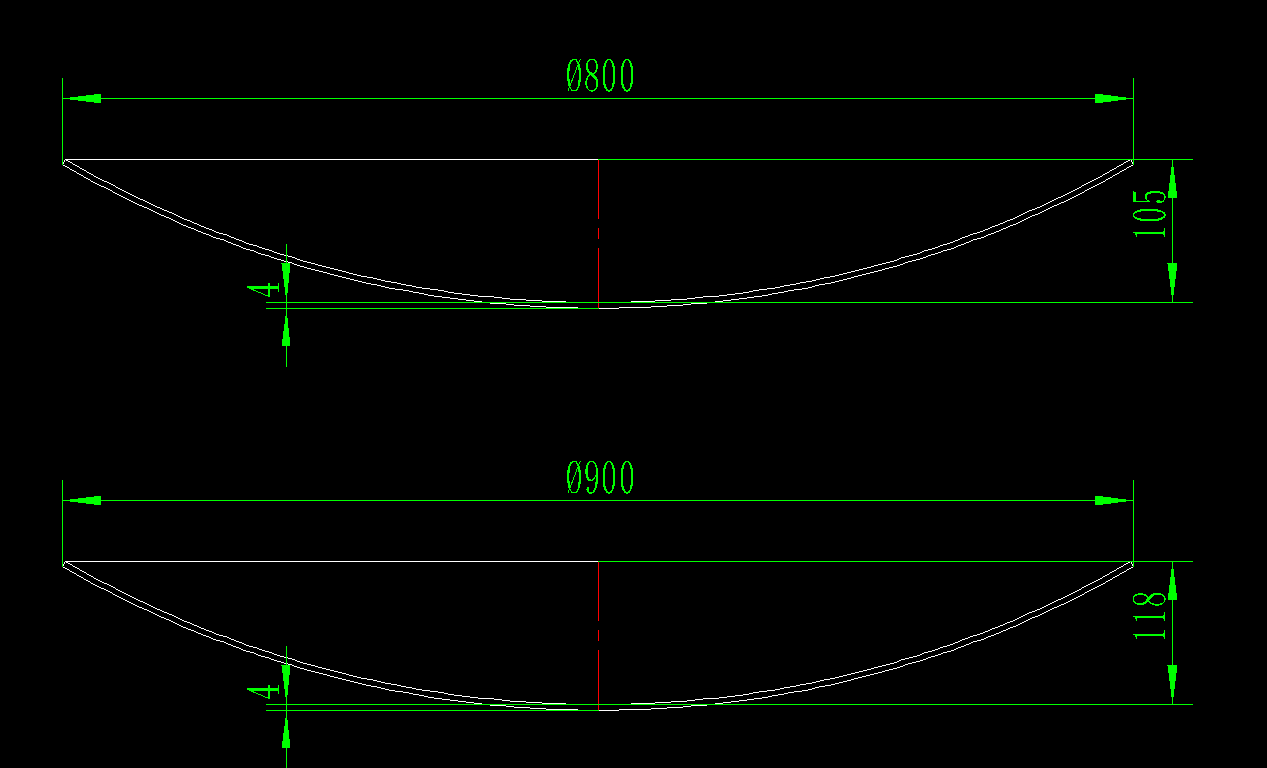

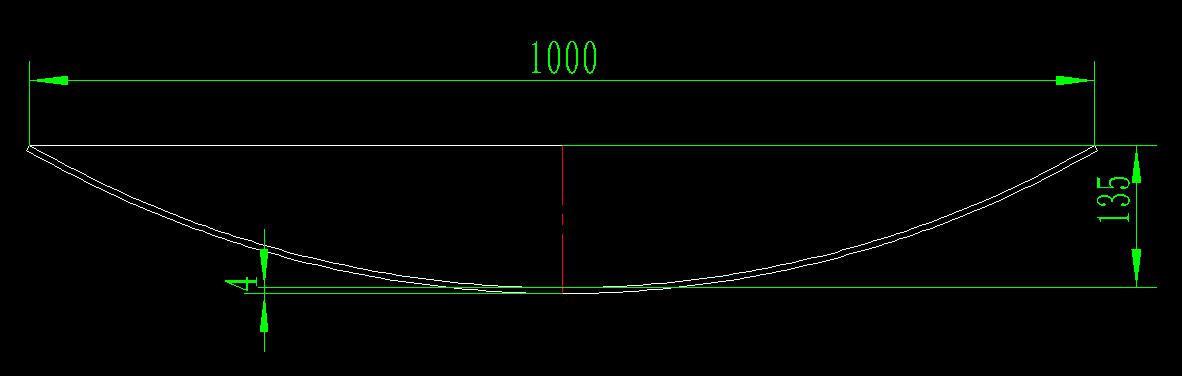

At Haipei Industry, we offer dished-only ends ranging from 89mm to 13 meters in diameter, with material thicknesses between 2mm and 400mm. Our team collaborates closely with clients to deliver components that align with their specifications.

Dished-only ends play a crucial role in industries where secure containment and structural strength are vital. Their applications include:

Storage Tanks: Used for liquid containment, such as fuel and chemical storage tanks.

Compartmentalization: Internally dividing tanks to create multiple compartments.

Industrial and Construction Uses: Supporting transportation, power, offshore, food and beverage, and other sectors.

Haipei Industry supplies dished-only ends to small and large-scale businesses, ensuring durability and performance across multiple industries.

Our dished-only ends are engineered to meet the highest standards of strength and reliability. We cater to diverse industries, including petrochemical, chemical, power generation, and water treatment, ensuring our products align with sector-specific requirements.

Haipei Industry employs advanced craftsmanship to manufacture dished-only ends that excel in structural integrity, containment, and stress distribution. Our expert team works closely with clients to ensure each product meets exacting specifications.

Quality is at the heart of our manufacturing process. Our dished-only ends conform to industry codes such as ASME, PED, and GB. We implement rigorous testing methods, including UT, RT, MT, PT, and TOFD, and hold certifications such as ISO9001, ISO45001, and OHSAS18001.

At Haipei Industry, we specialize in producing high-quality dished-only ends, pressure vessel heads, pipe caps, and more. We are committed to delivering superior products that align with industry demands and project requirements.

With worldwide delivery to Australia, New Zealand, and the broader Asia-Pacific region, we are your trusted partner for premium dished-only ends. Contact us today to discuss your project requirements and request a quote.

Production Process of Heads:

Manufacturer Supplier Dished End Elliptical Caps Stainless Steel Torispherical Dish Head

Picking steel---Cutting---Welding---Heating---Spinning---Stamping---Trimming---Defect detection---QC---Warehousing---Transporttation

Company Information

Haipei Industry is a specialized manufacturer of tank head. With over 30 years of engineered driven expertise ,it is a recognized leader within the tank head industry in china.With unique head forming, fabrication and heat treating capabilities, we offer a diversified range of products. Head diameters is from 3.5" to 393.7'', and Head thickness is from 0.078" to 11.8''. Pressure vessel heads and tank ends are available in a broad range of sizes, shapes, thicknesses and material specifications.

The main products of the company are: shell plate, elliptical head,torispherical heads,spherical dished heads, flat heads, spherical head, expansion joint, corrugated furnace and non-standard parts, and all kinds of stock heads are available for customers. The products are sold to more than 20 provinces and cities and regions in China and exported to foreign countries.

Advantages

♦ Small order advantage, flexibly in dealing with orders;

♦ Quality: Strict control of raw materials and the production process;

♦ Advanced technology,best quality,customer satisfaction,reputation first,good after-service;

♦No cracks , delamination, inclusion ,and other defects;

Our Services

1.No cracks,delamination, inclusion ,and other defects;

2.The warranty time is 6 months,except the wearing parts;

3.We provide the best service based on professional and sincerely attitude.

Product Pictures

Torispherical Head (also called torispherical dish end or torispherical ends) is widely applied for pressure tanks to storage liquids and gasses. The torispherical head consists of a spherical surface, a cylindrical edge of a certain height, and a transition section connecting the above two parts with a radius of curvature smaller than the radius of the sphere. Our asme torispherical head can be made with carbon steel, stainless steel, austenitic and non ferritic metals that can be cold worked. The stress distribution of torispherical dish head is not as uniform as elliptical head, but the manufacturing processing of the torispherical head is easier. However, torispherical dish end is the better option when the elliptical head of the mold processing is difficult. We can fabricate torispherical ends in most popular sizes and thicknesses.

Packaging & Shipping

Manufacturer Supplier Dished End Elliptical Caps Stainless Steel Torispherical Dish Head

6 pieces packed on a pallet for Large Spherical Outdoor Decorated steel firepit sphere

Wooden cases ,wooden pallet plastic bag or as per customers requirement

Contact us

Skype:frieda8368

Whatsapp/Weichat:86-18264838918

Email:[email protected]

FAQ

Q: What’s the information should I provide when inquiry?

A: Thanks for your question. If you have drawings, we will be entirely in accordance with production drawings . If you do not have the drawing, you can tell me the product data. There are several important data, such as material, type of head( We have elliptical head, hemispherical head, dished head, flat head, etc. ),diameter, thickness, special tolerances or requirements. We can do the drawings according to your requirements, and you confirm that the final product drawings.

Q: what are surface treatment of the product?

A:Thanks for your question. For carbon steel products, we sandblasting descaling product surface. For stainless steel products, we use acid to remove surface oil and impurities.

Q: How do you ensure the quality of products?

A: Thanks for your question.Our production staff is trained through national quality department, and obtain the corresponding certificate, with years of production and design experience. Weld must undergo X-ray inspection to ensure that no defects.

Q: Can you help us matching related products?

A: Thanks for your question. Our company also is surrounded by a lot of ancillary businesses, such as flanges, boiler, oil refining equipment, etc. We can help you matching the highest quality products with the lowest prices .

Contact: Frieda

Phone: +86 182 6483 8918

E-mail: [email protected]

Add: No.76,South.Road,Daiyue District,Tai'an,Shandong Province