Material:Carbon Steel;Stainless Steel; Aluminum; Exotic Alloys; Special Steel...

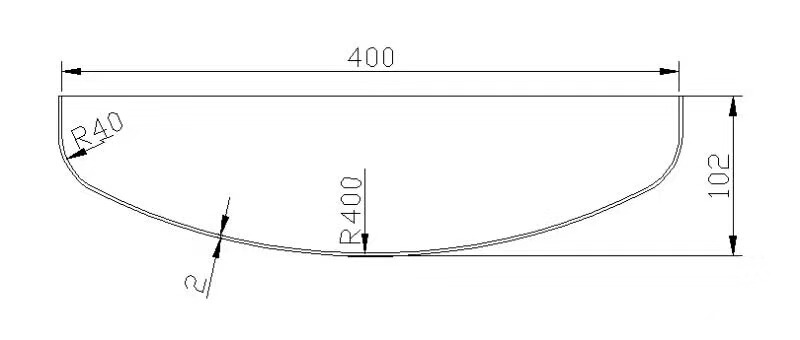

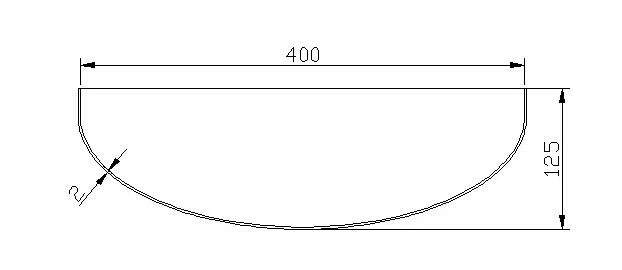

Diameter: 89 mm - 13000 mm

Thickness: 3-400mm

Technology: 1.Cold & Hot forming ;2. Hot Pressed Hemispheres and Cold Formed Segmental Hemispheres;

Applications:Such as oil, chemical industry, water conservancy, electric power, boiler, machinery, metallurgy, sanitary construction etc.

The ASME Pressure Vessel Dished Heads Elliptical Tank Head is a high-quality tank component designed for use in pressure vessels and storage tanks across various industries. Manufactured using advanced forming technologies such as hot pressing and cold pressing, these tank heads offer superior mechanical properties, corrosion resistance, and durability.

The following table provides key specifications for the ASME Pressure Vessel Dished Heads Elliptical Tank Head:

| Parameter | Specification |

|---|---|

| Diameter | 89 mm - 13,000 mm |

| Thickness | 2 mm - 400 mm |

| Reduction Ratio | Approximately 10% |

| Material | Carbon Steel (A3, 20#, Q235, Q345B, 16Mn) |

| Alloy Steel (15Mo3, 15CrMoV, 35CrMoV, 45CrMo) | |

| Stainless Steel (304, 321, 304L, 316, 316L) | |

| Technology | Hot Pressing, Cold Pressing |

| Surface Treatment | Sand Blasting, Transparent Oil, Rust-proof Oil, Galvanizing |

| Testing Methods | UT, RT, MT, PT, ET |

| Applicable Standards | ANSI, ASME, MSS, API, DIN, JIS, BS, AWWA, GB |

| Certificates | ISO9001, ISO14001, OHSAS18001 |

High Strength & Durability: Manufactured with premium materials and strict quality control.

Corrosion Resistance: Available in stainless steel and coated surfaces for enhanced longevity.

Customizable Sizes & Thickness: Wide range of diameters and thickness options.

Strict Quality Control: Certified under ISO standards and tested using advanced NDT methods.

Industry Compliance: Manufactured per ANSI, ASME, API, and other international standards.

Versatile Applications: Used in oil, chemical, water conservancy, power, boiler, machinery, metallurgy, and sanitary construction industries.

The elliptical tank heads are produced through a precise and controlled manufacturing process to ensure high quality and performance. The key processing steps include:

Material Selection & Cutting: High-quality steel sheets are selected and cut to size.

Welding & Heating: If required, materials are welded and heated for shaping.

Forming Process: Hot pressing or cold pressing to achieve the desired elliptical shape.

Trimming & Surface Treatment: Edges are trimmed, and surfaces undergo sandblasting, pickling, or polishing.

Non-Destructive Testing (NDT): UT, RT, MT, PT, and ET tests ensure structural integrity.

Final Inspection & Packaging: Quality-checked tank heads are packed for shipment.

These elliptical tank heads are widely used in:

Pressure Vessels: Storage tanks for gas and liquid substances.

Boilers & Heat Exchangers: Used in power plants and industrial heat applications.

Chemical & Petrochemical Processing: Corrosion-resistant tank heads for aggressive environments.

Food & Beverage Industry: Hygienic stainless steel heads for storage tanks.

Pharmaceutical Industry: Precision-engineered heads for high-purity applications.

The ASME Pressure Vessel Dished Heads Elliptical Tank Head is carefully packaged to prevent damage during transit. Standard packaging methods include:

Plywood Box

Plywood or Steel Pallet

Customized Packaging as per Customer Requirements

| Delivery Details | Specifications |

| Lead Time | 15 - 20 Days |

| Shipping Methods | DHL, FedEx, UPS, TNT (for samples); Ocean Freight (for bulk orders) |

| Payment Terms | T/T (30% deposit, 70% before delivery), L/C, PayPal (for samples) |

| Price Terms | EXW, FOB, CIF, CFR, DDP, DDU, DAP |

We offer full customization options, including:

Special designs per customer drawings.

High-temperature and corrosion-resistant coatings.

Strict adherence to ISO9001:2000 quality management.

Complete conformity inspection before delivery.

With over 33 years of manufacturing experience, we have established long-term relationships with clients worldwide. Our commitment to quality and customer satisfaction has made us a trusted supplier of high-performance tank heads.

For more information or to request a quote, feel free to contact us today!

Company information

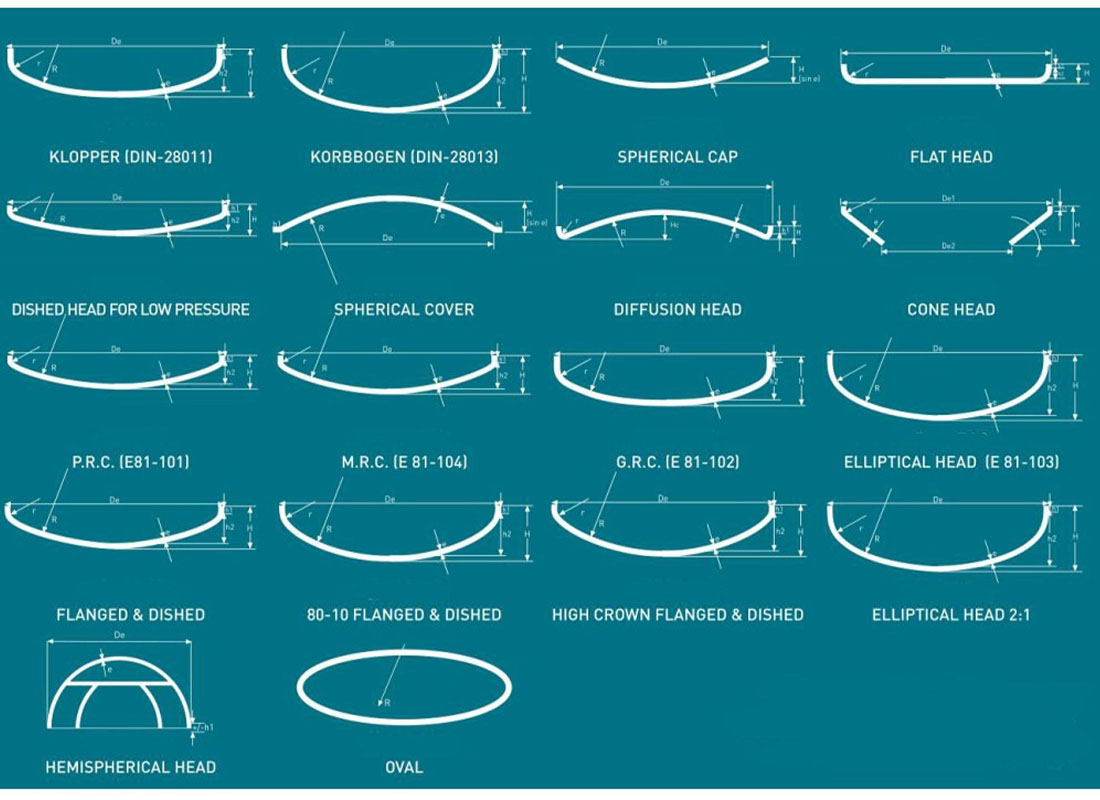

Haipei industry can produce all types of dished ends heads. They can be manufactured from a number of steel types including pressure vessel and boiler quality, chrome moly and stainless steel. The company also offers 2:1 semi ellipsodial, hemispherical petals, torispherical ends as well as conical knuckled sections.

Haipei industry company is a leading producer of various types of dished heads, cones, and other special pressed products in different materials grades like Carbon Steel, Stainless Steel, Duplex, Super Duplex, Aluminum, Nickel and Nickel Alloys, Copper and Copper Alloys, Titanium and Its Alloys, Zirconium and all cladded material combinations.

Our Services

We offer our products in the following materials:

Carbon Steel: SA36, SA516-70, SA387 Grade 5 Class 2 (Forming Only), SA285 Grade C (Forming Only)

Stainless Steel: SA240T304/304L, SA240T316/316L, SA240T304H (Forming Only), SA240T904/904L (Forming Only)

Copper: O-Temper Material (Forming Only)

Aluminum: O-Temper Material (Forming Only)

Quality assurance

Quality is the most important aspect of strength.We will make the material from the material to the end of the monitoring, making sure that each part can be of high quality according to the regulations.Each program will be monitored to ensure any errors in the manufacturing process.

Competitive price guarantee

With years of experience, we can offer our customers the most competitive prices.At the same time, as a powerful factory, we can offer customers more favorable prices than other factories.

Delivery time guarantee

We will strictly control the manufacturing schedule to ensure punctual delivery.It can satisfy the customer's time schedule and ensure the continuous production of customers.

Packaging & Shipping

ASME Pressure Vessel Dished Heads Elliptical Tank Head

1. Iron Frame2. Wooden Box3. Iron pallet4.Wooden pallet.5.Professional fixation6. Curstomed requirment

FAQ

Q: What’s the information should I provide when inquiry?

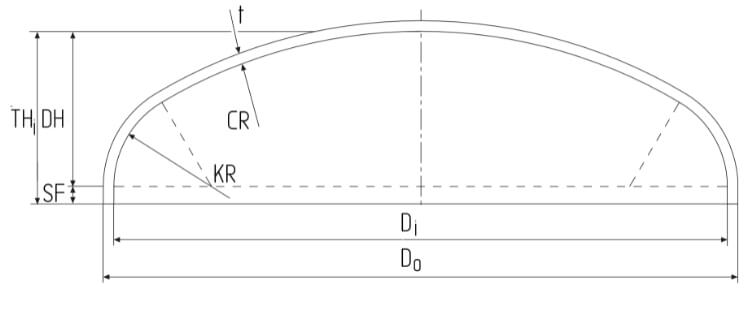

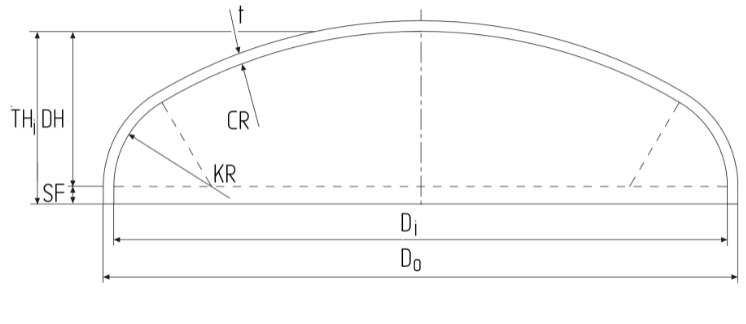

A: Thanks for your question. If you have drawings, we will be entirely in accordance with production drawings . If you do not have the drawing, you can tell me the product data. There are several important data, such as material, type of head( We have elliptical head, hemispherical head, dished head, flat head, etc. ),diameter, thickness, special tolerances or requirements. We can do the drawings according to your requirements, and you confirm that the final product drawings.

Q: what are surface treatment of the product?

A:Thanks for your question. For carbon steel products, we sandblasting descaling product surface. For stainless steel products, we use acid to remove surface oil and impurities.

Q: How do you ensure the quality of products?

A: Thanks for your question.Our production staff is trained through national quality department, and obtain the corresponding certificate, with years of production and design experience. Weld must undergo X-ray inspection to ensure that no defects.

Q: Can you help us matching related products?

A: Thanks for your question. Our company also is surrounded by a lot of ancillary businesses, such as flanges, boiler, oil refining equipment, etc. We can help you matching the highest quality products with the lowest prices .

Contact us

Contact: Frieda

Phone: +86 182 6483 8918

E-mail: [email protected]

Add: No.76,South.Road,Daiyue District,Tai'an,Shandong Province