Customized size

ASME standard

Reliable quality

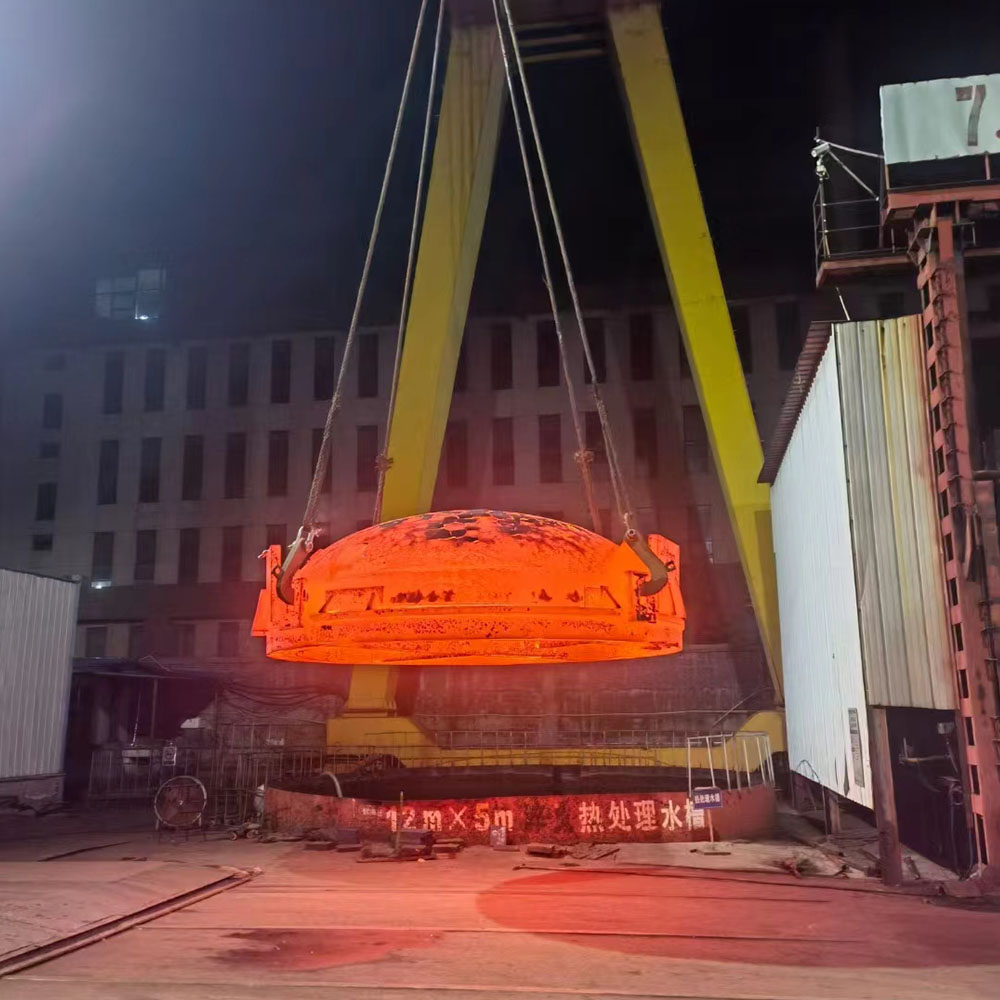

Hot press

Dameter 300mm to 13000mm

Thickness 2mm to 400mm

Introduction to Hemispherical Heads

Hemispherical heads, also known as hemispherical tank heads or hemispherical dished ends, are widely recognized for their superior mechanical properties and efficient material usage. These heads consist of half a spherical shell with a short cylindrical edge, making them an ideal choice for various industrial applications, particularly in pressure vessels.

Advantages of Hemispherical Heads

One of the key advantages of hemispherical heads is their ability to evenly distribute internal pressure across the entire surface. This unique feature enhances structural integrity and ensures maximum durability, making them highly reliable for liquid and gas storage tanks. Additionally, the hemispherical design allows for improved efficiency in combustion chambers, reducing heat loss and accommodating larger intake and exhaust valves in engine applications.

Technical Specifications

Diameter: Available in sizes ranging from 20” to 72” (customizable up to 5000 mm)

Material Thickness: Ranges from 10 gauge to 3/8” plate (2 mm to 200 mm)

Dish Radius: Equal to 50% of the diameter

Materials Available:

Carbon steel tank ends/caps: SA516 GR60N, GR70N

Stainless steel ellipsoidal dished end, elliptical tank head: SA240 304, 316

Titanium alloy pressure vessel ends: SB256 GR1, GR2, GR5

Manufacturing Technology: Cold pressing and hot pressing techniques

Surface Treatment: Options include pickling, sandblasting, or customized treatments

Applications of Hemispherical Heads

Due to their outstanding pressure distribution capabilities, hemispherical heads are extensively used in various industries, including:

Pressure Vessels: ASME heads, large hemisphere ends, small stainless hemisphere heads for tube ends, carbon steel hemisphere heads for boiler tops

Heat Exchangers: Facilitating efficient thermal exchange in industrial processes

Tanks & Storage Containers: Providing durable solutions for liquid and gas storage

Petroleum & Chemical Industry: Used in water conservancy, electric power, boilers, machinery, metallurgy, and sanitary construction

Selection Considerations for Vessel Heads

When selecting vessel heads, the following factors should be considered:

Customer Requirements – Customization options based on application needs.

Chemical Process Requirements –

Conical heads for vertical vessels with solid masses to aid in flow and discharge.

Elliptical or spherical heads for liquid masses.

Stirred pressure vessels should match the head shape with slurry leaf design and flow form.

Pressure Considerations –

Medium and low-pressure vessels often use ellipsoidal heads.

High and ultra-high-pressure vessels typically use spherical heads.

Stress Analysis –

If ellipsoidal heads have large openings that cause excessive local stress, spherical heads may be preferred.

Certifications and Quality Assurance

Our hemispherical heads adhere to the highest quality standards and are certified under ISO9001:2015, ensuring superior performance and reliability in demanding industrial applications.

Packing and Delivery

Hemispherical heads are carefully packed in wooden boxes and iron shelves to ensure safe transportation. We offer customizable packaging options to meet specific customer requirements. Standard delivery time is approximately 30 days, depending on order specifications.

Conclusion

With their optimal shape, exceptional strength, and wide range of applications, hemispherical heads provide an excellent solution for industries requiring high-performance pressure containment. Available in various sizes, materials, and surface treatments, these heads deliver unmatched durability and efficiency, making them the preferred choice for industrial and engineering applications.

Company information

Haipei industry can produce all types of dished ends heads. They can be manufactured from a number of steel types including pressure vessel and boiler quality, chrome moly and stainless steel. The company also offers 2:1 semi ellipsodial, hemispherical petals, torispherical ends as well as conical knuckled sections.

Haipei industry company is a leading producer of various types of dished heads, cones, and other special pressed products in different materials grades like Carbon Steel, Stainless Steel, Duplex, Super Duplex, Aluminum, Nickel and Nickel Alloys, Copper and Copper Alloys, Titanium and Its Alloys, Zirconium and all cladded material combinations.

Our Services

We offer our products in the following materials:

Carbon Steel: SA36, SA516-70, SA387 Grade 5 Class 2 (Forming Only), SA285 Grade C (Forming Only)

Stainless Steel: SA240T304/304L, SA240T316/316L, SA240T304H (Forming Only), SA240T904/904L (Forming Only)

Copper: O-Temper Material (Forming Only)

Aluminum: O-Temper Material (Forming Only)

Quality assurance

Quality is the most important aspect of strength.We will make the material from the material to the end of the monitoring, making sure that each part can be of high quality according to the regulations.Each program will be monitored to ensure any errors in the manufacturing process.

Competitive price guarantee

With years of experience, we can offer our customers the most competitive prices.At the same time, as a powerful factory, we can offer customers more favorable prices than other factories.

Delivery time guarantee

We will strictly control the manufacturing schedule to ensure punctual delivery.It can satisfy the customer's time schedule and ensure the continuous production of customers.

Packaging & Shipping

Carbon steel Hemispherical spherical head for Industrial hot blast stove

1. Iron Frame2. Wooden Box3. Iron pallet4.Wooden pallet.5.Professional fixation6. Curstomed requirment

FAQ

Q: What’s the information should I provide when inquiry?

A: Thanks for your question. If you have drawings, we will be entirely in accordance with production drawings . If you do not have the drawing, you can tell me the product data. There are several important data, such as material, type of head( We have elliptical head, hemispherical head, dished head, flat head, etc. ),diameter, thickness, special tolerances or requirements. We can do the drawings according to your requirements, and you confirm that the final product drawings.

Q: what are surface treatment of the product?

A:Thanks for your question. For carbon steel products, we sandblasting descaling product surface. For stainless steel products, we use acid to remove surface oil and impurities.

Q: How do you ensure the quality of products?

A: Thanks for your question.Our production staff is trained through national quality department, and obtain the corresponding certificate, with years of production and design experience. Weld must undergo X-ray inspection to ensure that no defects.

Q: Can you help us matching related products?

A: Thanks for your question. Our company also is surrounded by a lot of ancillary businesses, such as flanges, boiler, oil refining equipment, etc. We can help you matching the highest quality products with the lowest prices .

Contact us

Contact: Frieda

Phone: +86 182 6483 8918

E-mail: [email protected]

Add: No.76,South.Road,Daiyue District,Tai'an,Shandong Province