Material:Carbon Steel;Stainless Steel; Aluminum; Exotic Alloys; Special Steel...

Diameter: 89 mm - 13000 mm

Thickness: 3-400mm

Technology: 1.Cold & Hot forming ;2. Hot Pressed Hemispheres and Cold Formed Segmental Hemispheres;

Test:UT,RT,MT,PT,ET

Tank Head and Bottoms

Product Description

1. Grade: Carbon steel, Stainless steel, Aluminum,Titanium,etcAccording to customers requirement.

2. Size: 89mm--10000mm

3. Standard: ANSI, ASME ,MSS, API, DIN, JIS

4. Certification: ISO9001 ,ISO14001,OHSAS18001

5.Name: Bottom Tank Head Price,Steel Dished End/Elliptical Head/Hemispherical Head

Item: | Tank Head and Bottoms |

Diameter: | 89mm--13000mm |

Thickness: | 2mm--400mm |

Reduction Ratio: | about 10% |

Material: | Carbon stee(A3,20#,Q235,Q345B,16Mn), Alloy steel(15Mo3 15CrMoV 35CrMoV 45CrMo), |

Stainless steel (304,321,304L,316,316L), etc | |

According to customers requirement (If you can use Chinese material is the best.) | |

Technology: | Hot pressing, cold pressing |

Surface Treatment: | Sand Blasting, Transparent oil, Rust-proof oil, Galvanizing |

Test: | UT,RT,MT,PT,ET |

Applicable Standard | ANSI, ASME ,MSS, API, DIN, JIS, BS. AWWA and GB |

Certificate: | ISO9001 ,ISO14001,OHSAS18001 |

Applications: | Such as: oil, chemical industry, water conservancy, electric power, |

boiler, machinery, metallurgy, sanitary construction etc. | |

Product Character | Rustproof, good corrosion resistance, anti-wearing, good-appearance, excellent mechanical properties. |

Connection | Butt-welding |

Packaging: | Standard seaworthy export packing: Plywood Box, Plywood or Steel Pallet or as per customers requirement |

Delivery time: | According to customers requirement |

OEM,ODM | Available |

Others: | 1. Special design available according to your drawing. |

2. Anti-corrosion and high-temperature resistant with black painting | |

3. All the production process are made under the ISO9001:2000 strictly. | |

4. A conformity rate of ex-factory inspection of products.

|

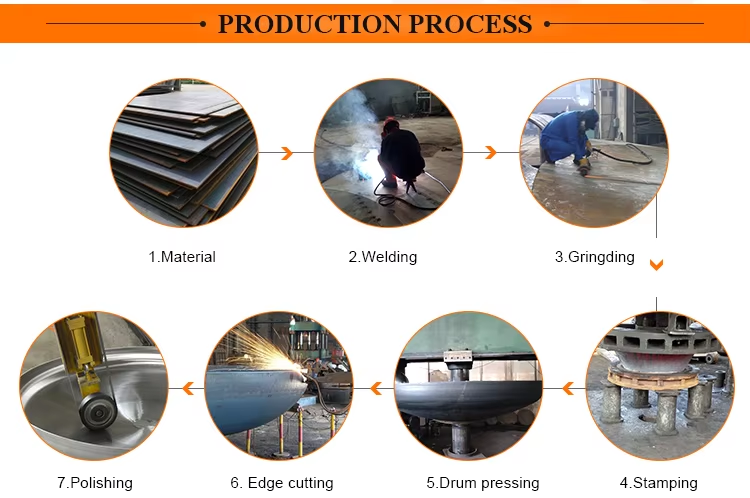

Producing-Process

Tank Head and Bottoms

Picking steel---Cutting---Welding---Heating---Spinning---Stamping---Trimming---Defect detection---QC---Warehousing---Transportation

Product Show

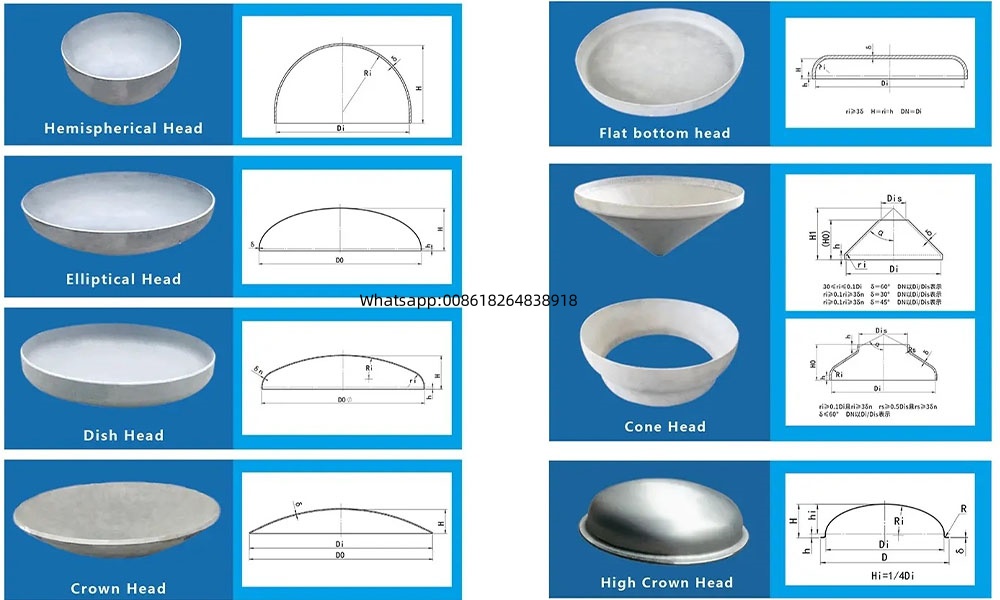

Hemispherical Head (also called hemispherical tank heads or hemispherical dish ends) is widely applied to make pressure tanks to storage liquids and gasses. Our asme hemispherical head is often made with carbon steel, stainless steel, austenitic and non ferritic metals that can be cold worked. Hemispherical is the ideal shape for development of hemispherical dish end, because the pressure in the vessel is divided equally across the surface of the head. The radius (Ri) of the head equals the radius of the cylindrical part of the vessel. This type of hemispherical tank heads or hemispherical dish ends are made in most popular sizes and thicknesses.

Ellipsoidal head (also called elliptical head or elliptical dish end) is usually made with Carbon steel, stainless steel, austenitic and non ferritic metals that can be cold worked. The shape of this ellipsoidal head is more economical, because the height of the head is just a fraction of the diameter. The elliptical dish end radius varies between the major and minor axis usually with the ratio is 2:1. The elliptical tank head is the economical solution for medium pressure tanks due to the reduced metal thickness requirement.

We can produce up to 8,000 mm diameter asme torispherical dish end depending upon thickness of material and wall thickness up to 30 mm depending upon material and diameter. custom forms and dimensions are also available.

Torispherical Head (also called torispherical dish end or torispherical ends) is widely applied for pressure tanks to storage liquids and gasses. The torispherical head consists of a spherical surface, a cylindrical edge of a certain height, and a transition section connecting the above two parts with a radius of curvature smaller than the radius of the sphere. Our asme torispherical head can be made with carbon steel, stainless steel, austenitic and non ferritic metals that can be cold worked. The stress distribution of torispherical dish head is not as uniform as elliptical head, but the manufacturing processing of the torispherical head is easier. However, torispherical dish end is the better option when the elliptical head of the mold processing is difficult. We can fabricate torispherical ends in most popular sizes and thicknesses.

Conical Head (also called the tapered tank head) is widely used for vessel bottom or cover plates. With the shape of concentric cone, the toriconical head consists of a large end cone and a small end. Cone and large end of the connection, due to geometric discontinuity, the radius of curvature of the mutation, so there will be a large lateral thrust, causing a large edge stress, prone to bending, it is necessary to strengthen.the tapered head The cone head type is divided into CHA (30), CHA (45), CHA (60) by half angle.

Packaging & Shipping

FAQ

A: Thanks for your question. If you have drawings, we will be entirely in accordance with production drawings . If you do not have the drawing, you can tell me the product data. There are several important data, such as material, type of head( We have elliptical head, hemispherical head, dished head, flat head, etc. ),diameter, thickness, special tolerances or requirements. We can do the drawings according to your requirements, and you confirm that the final product drawings.

A:Thanks for your question. For carbon steel products, we sandblasting descaling product surface. For stainless steel products, we use acid to remove surface oil and impurities.

A: Thanks for your question.Our production staff is trained through national quality department, and obtain the corresponding certificate, with years of production and design experience. Weld must undergo X-ray inspection to ensure that no defects.

A: Thanks for your question. Our company also is surrounded by a lot of ancillary businesses, such as flanges, boiler, oil refining equipment, etc. We can help you matching the highest quality products with the lowest prices .

Contact: Frieda

Phone: +86 182 6483 8918

E-mail: [email protected]

Add: No.76,South.Road,Daiyue District,Tai'an,Shandong Province