Material:Carbon Steel;Stainless Steel; Aluminum; Exotic Alloys; Special Steel...

Diameter: 89 mm - 13000 mm

Thickness: 3-400mm

Technology: 1.Cold & Hot forming ;2. Hot Pressed Hemispheres and Cold Formed Segmental Hemispheres;

Test:UT,RT,MT,PT,ET

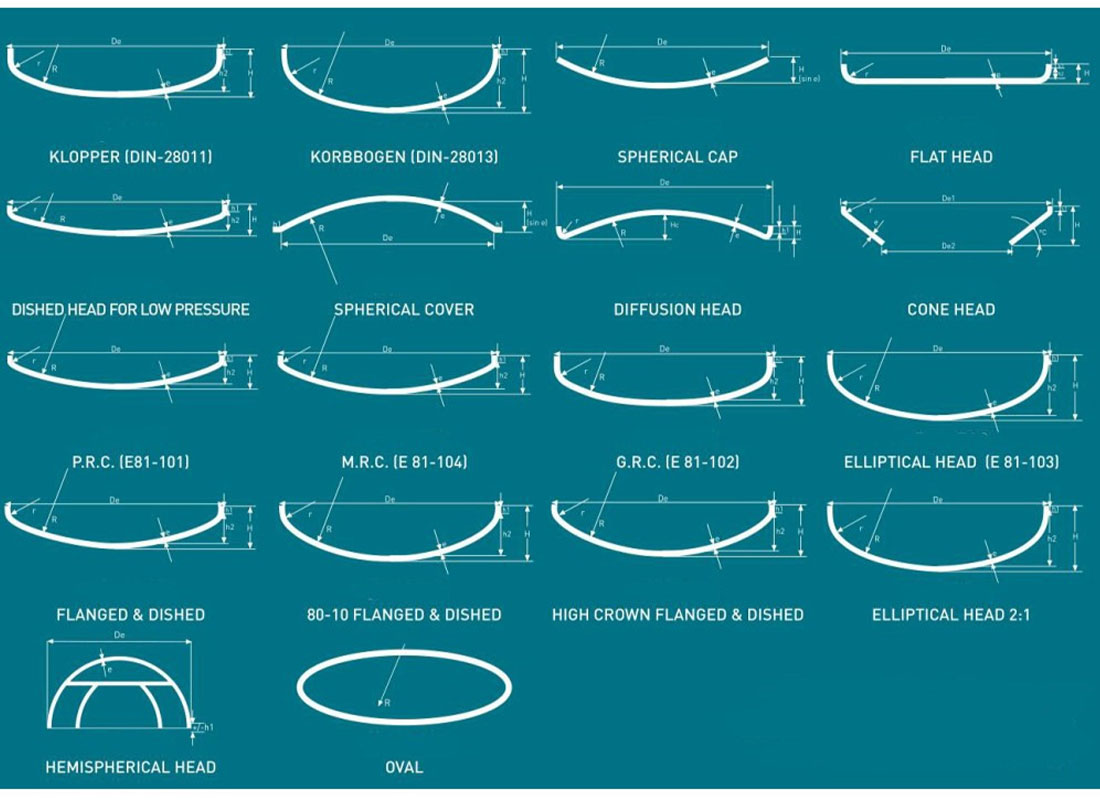

Pressure Vessels Heads Dish Ends Formed Heads

Product Description

Pressure vessel heads are crucial components of a pressure vessel, serving as the end closures for its cylindrical shell. These heads help maintain the integrity of the vessel by containing internal pressure. Various names are commonly used for these components, including Dish Ends, Formed Heads, End Closures, End Caps, Vessel Ends, and Vessel Caps. However, the most widely recognized term is "Dish Ends."

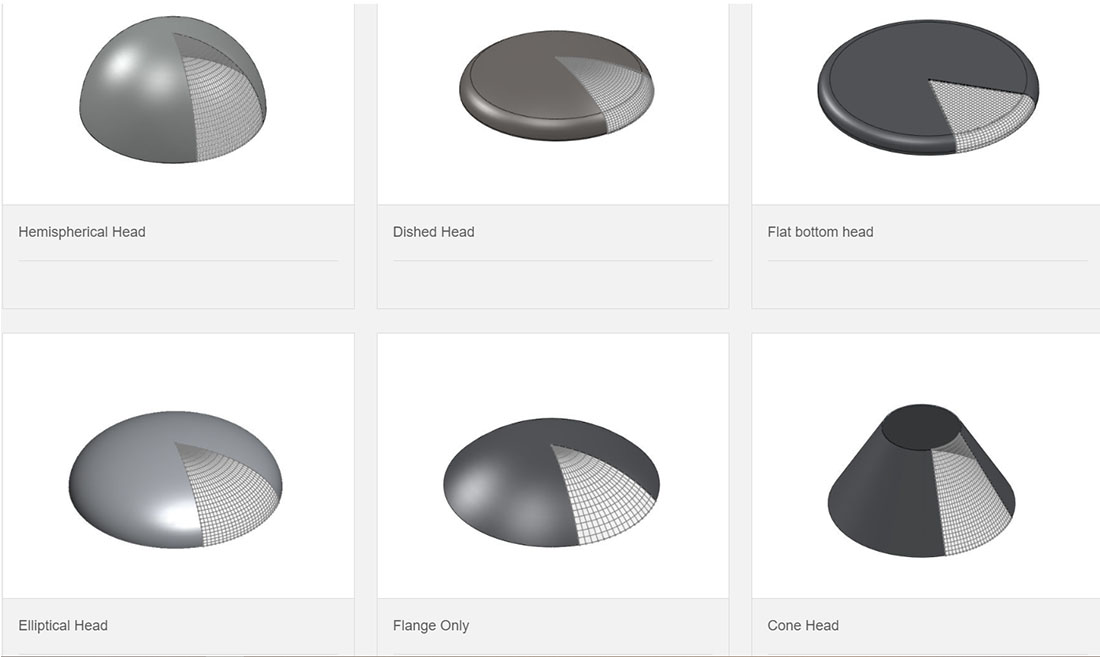

There are four primary types of pressure vessel heads commonly used in fabrication:

Flat Heads

Ellipsoidal Heads

Torispherical Heads (Flange and Dished Heads)

Hemispherical Heads

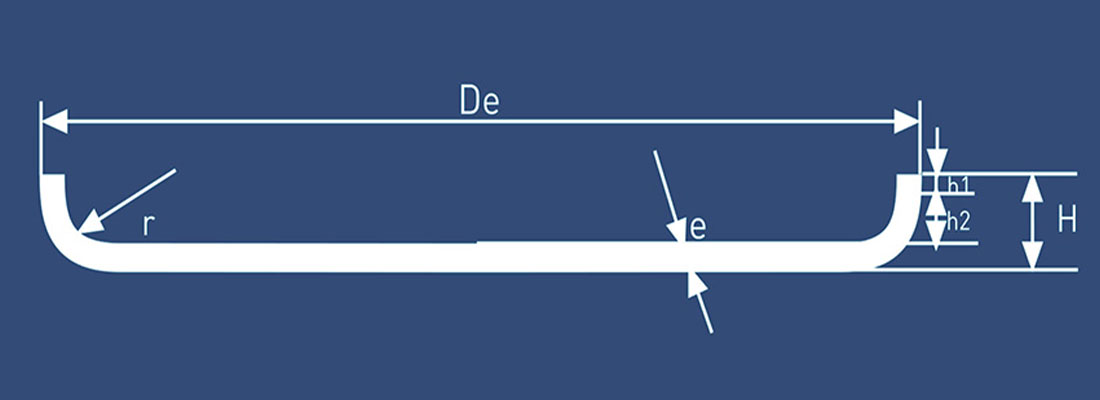

Flat heads are the simplest type of pressure vessel heads, but they are less frequently used due to their lower ability to withstand pressure. Since they have a reduced radial section for pressure distribution, the flat surface bears the majority of the stress, making them less economical for high-pressure applications.

Key Terms in Flat Heads:

Flat Head Inside Diameter (ID)

Knuckle Radius (R)

Dish End Total Height (H)

Straight Face (SF)

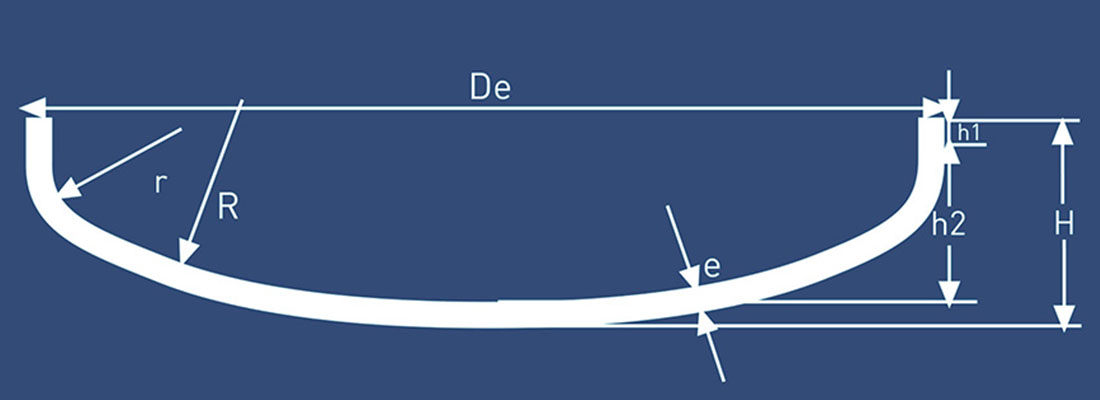

Ellipsoidal heads are the most commonly used pressure vessel heads. Their wider radial section allows for better pressure distribution, making them more capable of handling high pressures compared to other types. These heads are highly preferred due to their efficiency and cost-effectiveness. Typically, a 2:1 ellipsoidal head configuration is used, meaning the major axis is twice the length of the minor axis.

Key Terms in 2:1 Ellipsoidal Heads:

Inside Diameter (ID)

Crown Radius (C.R)

Knuckle Radius (K.R)

Dish End Total Height (H)

Straight Face (SF)

| Head Type | Pressure Withstanding Capacity | Economical | Forming Time |

|---|---|---|---|

| Flat Heads | Low | Low | Low |

| Ellipsoidal Heads | High | High | Moderate |

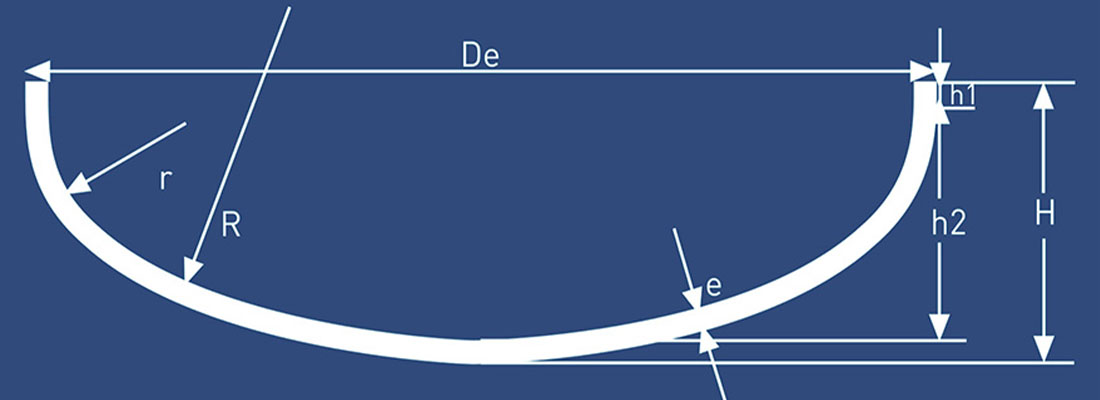

Torispherical heads are another widely used type of pressure vessel head. They offer good pressure distribution, though slightly lower than ellipsoidal heads. One advantage of torispherical heads is their reduced forming time compared to ellipsoidal heads, making them a popular choice for fabrication.

For the same design conditions, the thickness of torispherical heads is approximately 1.77 times the thickness of the shell for equal design pressure and temperature.

Key Terms in Torispherical Heads:

Inside Diameter (ID)

Crown Radius (C.R)

Knuckle Radius (K.R)

Dish End Total Height (H)

Straight Face (SF)

Hemispherical heads provide the maximum available radial section, which results in superior pressure distribution. Due to this, for the same design conditions, the required thickness of a hemispherical head is roughly half the thickness of the shell for an equivalent pressure and temperature.

Though they are the most economical in terms of material usage, they require the most time for forming.

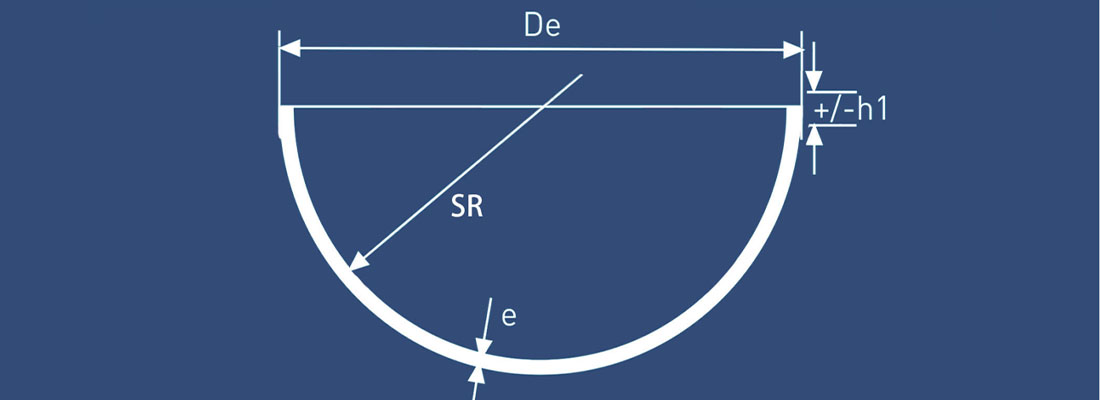

Key Terms in Hemispherical Heads:

Inside Diameter (ID)

Crown Radius (R)

Dish End Total Height (H)

Straight Face (SF)

| Head Type | Thickness Requirement | Forming Complexity |

| Torispherical Heads | 1.77 times shell thickness | Moderate |

| Hemispherical Heads | 0.5 times shell thickness | High |

These four primary types of pressure vessel heads are widely used in the fabrication of pressure vessels. The selection of a particular type depends on design conditions, pressure requirements, and manufacturing feasibility. Various calculations, including dish end dimensions, blank diameter, weight, surface area, and volume, are essential for fabrication. Proper selection and design ensure safety, efficiency, and cost-effectiveness in pressure vessel manufacturing.

Material | Carbon Steel;Stainless Steel; Aluminum; Exotic Alloys; Special Steel... |

Main Products | Torispherical; 2:1Semi Ellipsoidal; Hemispherical; Flat Bottom; Floating Heads; Tank Heads; Dish Heads; Dished Ends; Pipe Caps.... |

Surface Treatment | 1. Intermediate & Final stage Heat Treatments; |

Technology | 1.Cold & Hot forming ; |

Test | 1. Liquid Penetrant Examination; |

Production Process of Heads:

Dish Ends Calculator

Picking steel---Cutting---Welding---Heating---Spinning---Stamping---Trimming---Defect detection---QC---Warehousing---Transporttation

Company Information

Haipei Industry is a specialized manufacturer of tank head. With over 30 years of engineered driven expertise ,it is a recognized leader within the tank head industry in china.With unique head forming, fabrication and heat treating capabilities, we offer a diversified range of products. Head diameters is from 3.5" to 393.7'', and Head thickness is from 0.078" to 11.8''. Pressure vessel heads and tank ends are available in a broad range of sizes, shapes, thicknesses and material specifications.

The main products of the company are: shell plate, elliptical head,torispherical heads,spherical dished heads, flat heads, spherical head, expansion joint, corrugated furnace and non-standard parts, and all kinds of stock heads are available for customers. The products are sold to more than 20 provinces and cities and regions in China and exported to foreign countries.

Advantages

♦ Small order advantage, flexibly in dealing with orders;

♦ Quality: Strict control of raw materials and the production process;

♦ Advanced technology,best quality,customer satisfaction,reputation first,good after-service;

♦No cracks , delamination, inclusion ,and other defects;

Our Services

1.No cracks,delamination, inclusion ,and other defects;

2.The warranty time is 6 months,except the wearing parts;

3.We provide the best service based on professional and sincerely attitude.

Product Pictures

Torispherical Head (also called torispherical dish end or torispherical ends) is widely applied for pressure tanks to storage liquids and gasses. The torispherical head consists of a spherical surface, a cylindrical edge of a certain height, and a transition section connecting the above two parts with a radius of curvature smaller than the radius of the sphere. Our asme torispherical head can be made with carbon steel, stainless steel, austenitic and non ferritic metals that can be cold worked. The stress distribution of torispherical dish head is not as uniform as elliptical head, but the manufacturing processing of the torispherical head is easier. However, torispherical dish end is the better option when the elliptical head of the mold processing is difficult. We can fabricate torispherical ends in most popular sizes and thicknesses.

Packaging & Shipping

Dish Ends Calculator

6 pieces packed on a pallet for Large Spherical Outdoor Decorated steel firepit sphere

Wooden cases ,wooden pallet plastic bag or as per customers requirement

Contact us

Skype:frieda8368

Whatsapp/Weichat:86-18264838918

Email:[email protected]

FAQ

Q: What’s the information should I provide when inquiry?

A: Thanks for your question. If you have drawings, we will be entirely in accordance with production drawings . If you do not have the drawing, you can tell me the product data. There are several important data, such as material, type of head( We have elliptical head, hemispherical head, dished head, flat head, etc. ),diameter, thickness, special tolerances or requirements. We can do the drawings according to your requirements, and you confirm that the final product drawings.

Q: what are surface treatment of the product?

A:Thanks for your question. For carbon steel products, we sandblasting descaling product surface. For stainless steel products, we use acid to remove surface oil and impurities.

Q: How do you ensure the quality of products?

A: Thanks for your question.Our production staff is trained through national quality department, and obtain the corresponding certificate, with years of production and design experience. Weld must undergo X-ray inspection to ensure that no defects.

Q: Can you help us matching related products?

A: Thanks for your question. Our company also is surrounded by a lot of ancillary businesses, such as flanges, boiler, oil refining equipment, etc. We can help you matching the highest quality products with the lowest prices .

Contact: Frieda

Phone: +86 182 6483 8918

E-mail: [email protected]

Add: No.76,South.Road,Daiyue District,Tai'an,Shandong Province