Carbon and stainless steel 2:1 ASME semi-elliptical tank heads. In stock tank head sizes minimum order $ 400. Pricing and quantities are subject to change.

Tanks Ellipsoidal Heads Carbon Steel Pressure Vessel ASME 2: 1

Product Description

Elliptical carbon and stainless steel clad dished head is the main pressure-bearing part of the pressure vessel to close the end of the vessel for sealing, it is welded to the vessel shell.The main clad dish head materials is carbon steel and stainless steel,the common one is SA516Gr70 and 304,316 and so on.

It can be elliptical dish head,torispherical dish head ,flat dish head ,hemispherical dish head based on its shape.As a usual ,have carbon steel ,stainless steel material dish head,cald material dish head,standard have ASME ,GB .Size and thickness can be as your requirements.

Item: | Tanks Ellipsoidal Heads Carbon Steel Pressure Vessel ASME 2: 1 |

Diameter: | 89mm--13000mm |

Thickness: | 2mm--400mm |

Reduction Ratio: | about 10% |

Material: | Carbon stee(A3,20#,Q235,Q345B,16Mn), Alloy steel(15Mo3 15CrMoV 35CrMoV 45CrMo), |

Stainless steel (304,321,304L,316,316L), etc | |

According to customers requirement (If you can use Chinese material is the best.) | |

Technology: | Hot pressing, cold pressing |

Surface Treatment: | Sand Blasting, Transparent oil, Rust-proof oil, Galvanizing |

Test: | UT,RT,MT,PT,ET |

Applicable Standard | ANSI, ASME ,MSS, API, DIN, JIS, BS. AWWA and GB |

Certificate: | ISO9001 ,ISO14001,OHSAS18001 |

Applications: | Such as: oil, chemical industry, water conservancy, electric power, |

boiler, machinery, metallurgy, sanitary construction etc. | |

Product Character | Rustproof, good corrosion resistance, anti-wearing, good-appearance, excellent mechanical properties. |

Connection | Butt-welding |

Packaging: | Standard seaworthy export packing: Plywood Box, Plywood or Steel Pallet or as per customers requirement |

Delivery time: | According to customers requirement |

OEM,ODM | Available |

Others: | 1. Special design available according to your drawing. |

2. Anti-corrosion and high-temperature resistant with black painting | |

3. All the production process are made under the ISO9001:2000 strictly. | |

4. A conformity rate of ex-factory inspection of products.

|

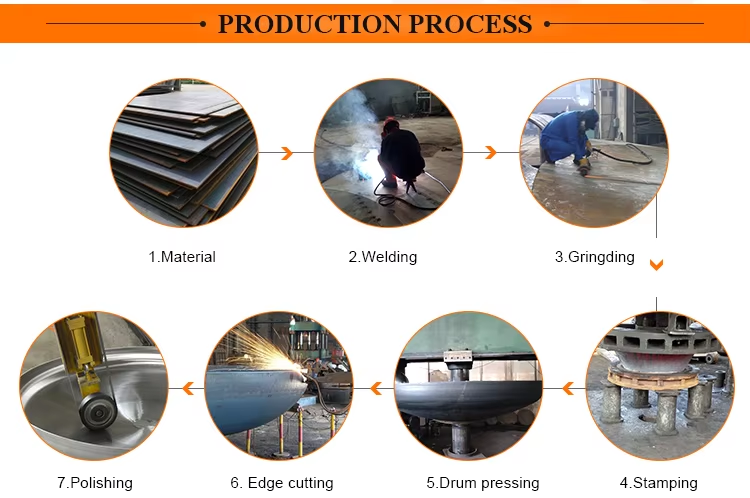

Producing-Process

Tanks Ellipsoidal Heads Carbon Steel Pressure Vessel ASME 2: 1

Picking steel---Cutting---Welding---Heating---Spinning---Stamping---Trimming---Defect detection---QC---Warehousing---Transportation

Product Show

Semi-Ellipsoidal and Torispherical Dished Heads: Essential Components for Vessels

In the creation of pressure vessels, storage tanks, and processing equipment, semi-ellipsoidal and torispherical dished heads, formed using a hot pressing method according to industry codes, are critical components widely utilized across many sectors.

A specific hot pressing technique gives these heads their characteristic semi-ellipsoidal or torispherical shape. This method shapes the steel within a defined temperature range that preserves the material's strength and robustness. Although the final shapes vary, the underlying production process remains the same.

Semi-ellipsoidal and torispherical hot-pressed code dished heads differ significantly in their geometry, curvature, and how they handle stress.

Semi-Ellipsoidal Heads

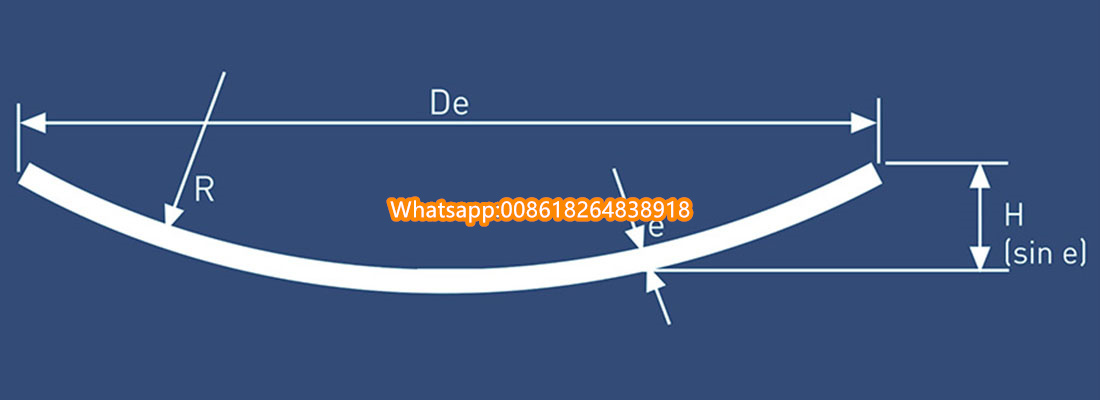

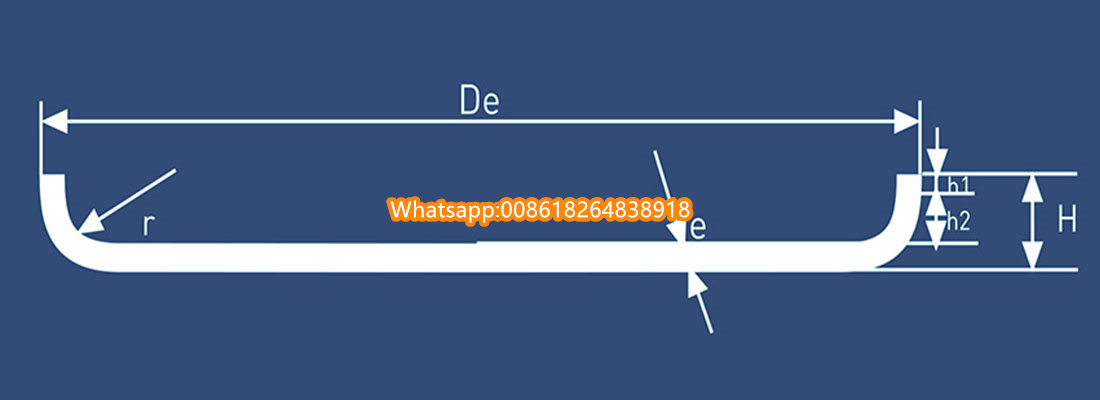

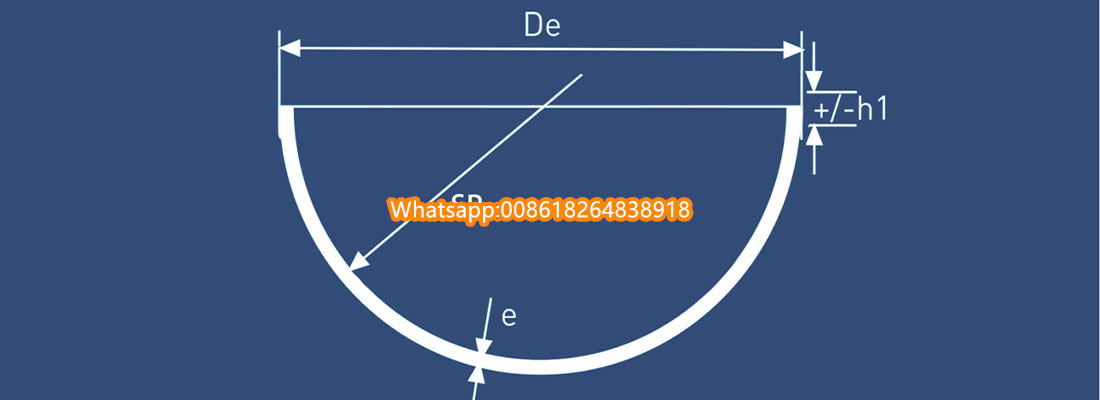

Semi-elliptical dished and flanged heads take on a form resembling a portion of an ellipsoid. Their deeper, more defined contour distinguishes them from torispherical types. This distinct shape makes them well-suited for applications requiring this form and capable of withstanding higher operating pressures due to their greater depth

Torispherical Heads

Torispherical dished and flanged heads possess a shallower profile compared to semi-ellipsoidal designs. They have a gentler, less dramatic curve, which makes them ideal when space is restricted. Furthermore, they are generally more cost-effective to manufacture, providing financial advantages.

Typical Applications of Dished Heads

Both semi-ellipsoidal and torispherical hot-pressed code dished heads find extensive use in numerous industries and applications, most notably in the fabrication of pressure vessels, storage tanks, and process vessels.

Their capacity to reinforce structural stability and ensure the secure containment of pressurized substances makes them indispensable in a variety of sectors, including:

At Haipei Dish Heads, our semi-ellipsoidal and torispherical hot-pressed code dished heads are meticulously crafted to meet diverse industry requirements. As reliable manufacturers of dished heads and elliptical heads, we guarantee the following to our customers.

Adaptable to Various Industries

We specialize in producing dished heads and ellipsoidal heads characterized by exceptional strength and dependability, all within a thoughtfully engineered design. Whether destined for the chemical, petrochemical, power generation, water treatment, or other industrial segments, our dished heads are designed to consistently deliver peak performance and long-term durability.

Advanced Design and Engineering

Our dished heads embody cutting-edge design principles and superior workmanship. Engineered to satisfy the demanding needs of diverse industrial applications, they ensure long life, structural integrity, and optimum stress distribution. Crucially, we can assist you in determining the ideal torispherical and semi-ellipsoidal dished head dimensions for your specific project.

Surpassing Industry Standards

Our semi-ellipsoidal and torispherical dished heads comply with strict industry standards, including ASME codes and other regulatory requirements. By meeting—and exceeding—these standards, we reassure our clients of their superior quality. We guarantee that each dished head will perform reliably, reflecting the precision engineering and high-quality materials that define Haipei Dish Heads.

The Right Solution for Your Industry

At Haipei Dish Heads, we offer a comprehensive range that extends beyond dished heads. Our high-performance product line includes pressure vessel heads, pipe caps, and more.

Our knowledgeable team is ready to help you identify the perfect solution to suit your specific industrial needs, prioritizing exceptional performance and reliability in all we do. We can address any inquiries, from ASME elliptical head dimensions to torispherical dished heads and everything in between.

Feature

1.Hard Materials Temperature and pressure resistance, corrosion resistance

2.Strong resistance to pressure Made of high-quality steel, strong pressure resistance

3.Long use time Not easy to rust, long use time, suitable for a variety of working environments

4.Stable chassis Standard thickness, good processing performance

5.Various specifications Various types of tank heads can be customized according to customer requirements

Packaging & Shipping

Carbon and stainless steel 2:1 ASME semi-elliptical tank heads. In stock tank head sizes minimum order $ 400. Pricing and quantities are subject to change.

FAQ

A: Thanks for your question. If you have drawings, we will be entirely in accordance with production drawings . If you do not have the drawing, you can tell me the product data. There are several important data, such as material, type of head( We have elliptical head, hemispherical head, dished head, flat head, etc. ),diameter, thickness, special tolerances or requirements. We can do the drawings according to your requirements, and you confirm that the final product drawings.

A:Thanks for your question. For carbon steel products, we sandblasting descaling product surface. For stainless steel products, we use acid to remove surface oil and impurities.

A: Thanks for your question.Our production staff is trained through national quality department, and obtain the corresponding certificate, with years of production and design experience. Weld must undergo X-ray inspection to ensure that no defects.

A: Thanks for your question. Our company also is surrounded by a lot of ancillary businesses, such as flanges, boiler, oil refining equipment, etc. We can help you matching the highest quality products with the lowest prices .

Contact: Frieda

Phone: +86 182 6483 8918

E-mail: [email protected]

Add: No.76,South.Road,Daiyue District,Tai'an,Shandong Province